This guide encapsulates the collective wisdom of automation disciplines, offering a structured approach to understanding and applying automation principles effectively.

A Body of Knowledge represents a comprehensive compilation of theories, practices, and skills within a specific field, ensuring standardized understanding and application.

Establishing a standardized Automation Body of Knowledge is crucial for consistent training, competency assessment, and ultimately, successful project execution across industries.

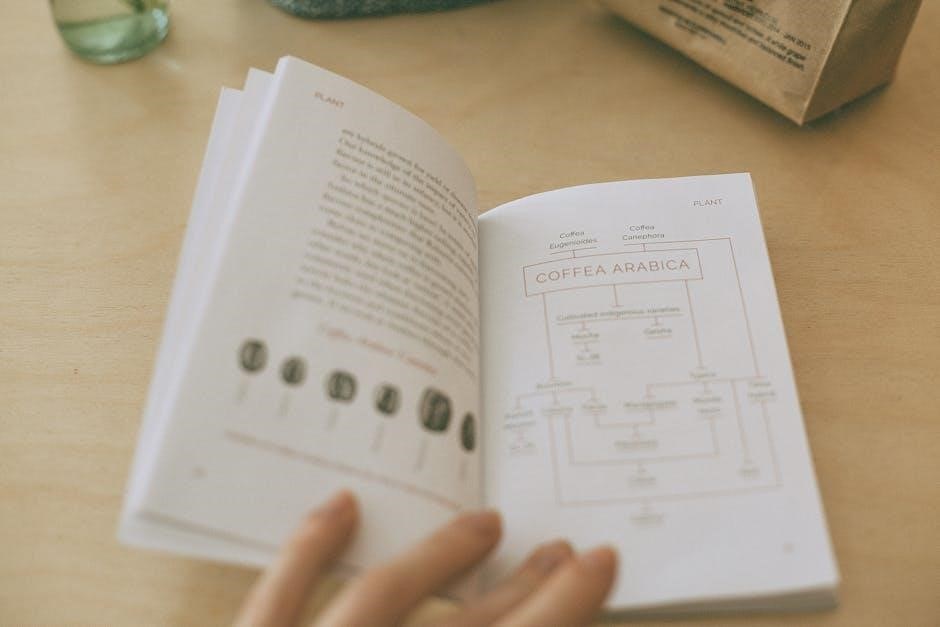

What is a Body of Knowledge?

A Body of Knowledge (BoK) is fundamentally the comprehensive collection of all known information, theories, disciplines, and practices relevant to a particular field of study or profession. It’s more than just a textbook; it represents the accumulated expertise and understanding developed over time by practitioners and researchers.

Think of it as a curated repository of everything someone needs to know to be considered competent in that area. This includes established principles, methodologies, best practices, and even the historical context that shaped the field. A well-defined BoK provides a common foundation for learning, certification, and professional development.

Crucially, a BoK isn’t static; it evolves as new discoveries are made and existing knowledge is refined, ensuring its continued relevance and accuracy. It serves as a benchmark for assessing skill levels and promoting consistent standards within the profession.

The Importance of a Standardized Automation Body of Knowledge

A standardized Automation Body of Knowledge is paramount for several reasons. It establishes a consistent baseline for training and competency, ensuring all automation professionals possess a shared understanding of core principles and practices. This uniformity minimizes errors, improves project outcomes, and enhances overall system reliability.

Furthermore, a BoK facilitates effective communication and collaboration between engineers, technicians, and stakeholders. It provides a common language and framework for discussing complex automation challenges. Standardized training, supported by resources like SCORM e-learning, ensures uniform delivery, though demonstrated capability requires more than completion status.

Ultimately, a well-defined BoK elevates the entire automation profession, fostering innovation and driving continuous improvement within the industry.

Domain 1: Feasibility Study

This domain focuses on identifying, scoping, and justifying potential automation projects, laying the groundwork for successful implementation and return on investment analysis.

Identifying Potential Automation Projects

The initial step involves a thorough assessment of existing processes to pinpoint areas ripe for automation. This requires a detailed understanding of current workflows, bottlenecks, and repetitive tasks that consume significant resources. Look for processes that are prone to human error, safety concerns, or those demanding high precision and consistency.

Consider factors like process volume, data availability, and the potential for integration with existing systems. Brainstorming sessions with process owners and subject matter experts are invaluable in generating a comprehensive list of potential projects. Prioritization should be based on factors like potential ROI, strategic alignment, and feasibility of implementation. Remember to document all identified opportunities for further evaluation.

Scoping the Automation Project

Clearly defining the project’s boundaries is paramount for success. This involves specifying exactly which processes will be automated, and crucially, which will remain manual. A detailed scope document should outline the project’s objectives, deliverables, and acceptance criteria. Consider the interfaces with other systems and the potential impact on existing workflows.

Break down the project into manageable phases, identifying key milestones and dependencies. Define the project’s limitations, including budgetary constraints, timeframes, and resource availability. A well-defined scope prevents “scope creep” and ensures the project stays focused on delivering the intended value. Stakeholder alignment on the scope is essential before proceeding.

Justifying the Automation Project – ROI Analysis

A robust Return on Investment (ROI) analysis is critical for securing project funding and demonstrating value. This involves quantifying both the costs and benefits of automation. Costs include equipment, installation, training, and ongoing maintenance. Benefits encompass increased efficiency, reduced labor costs, improved product quality, and enhanced safety.

Calculate key metrics like payback period, net present value (NPV), and internal rate of return (IRR). Consider both tangible and intangible benefits, such as improved employee morale and enhanced data accuracy. Present the ROI analysis in a clear and concise manner, highlighting the potential financial gains and strategic advantages of the automation project.

Domain 2: Definition

This domain focuses on precisely defining all necessary components – equipment, piping, and instrumentation – required for successful process automation implementation.

Defining Automation Requirements

Clearly articulating automation requirements is the cornerstone of any successful project. This involves a detailed examination of process needs, outlining specific functionalities, performance criteria, and safety protocols. Requirements must be measurable, achievable, relevant, and time-bound (SMART) to ensure clarity and avoid ambiguity.

Effective requirement definition necessitates collaboration between process engineers, control system specialists, and end-users. Documentation should encompass both functional requirements – what the system must do – and non-functional requirements, such as security, reliability, and maintainability. Utilizing standardized templates and employing techniques like use case analysis can significantly improve the quality and completeness of the defined requirements, ultimately minimizing risks and maximizing project success.

Equipment and Piping Specifications

Detailed specifications for equipment and piping are paramount in automation projects, ensuring compatibility, safety, and reliable operation. These specifications must encompass material selection, size, pressure ratings, and adherence to relevant industry standards (like ASME or API). Precise documentation minimizes procurement errors and facilitates seamless integration.

Piping specifications should define materials based on fluid compatibility, temperature, and pressure requirements, including weld joint details and non-destructive testing procedures. Equipment specifications must detail performance characteristics, power requirements, and control interfaces. Utilizing a standardized specification format, referencing ISA’s Automation Dictionary for precise terminology, is crucial for clear communication and accurate implementation throughout the project lifecycle.

Instrumentation and Control (A&C) Component Definition

Defining A&C components precisely is fundamental to successful automation. This involves specifying sensors (temperature, pressure, flow), transmitters, control valves, analyzers, and their associated signal types and ranges. Detailed specifications must include accuracy, resolution, response time, and environmental operating conditions.

Control system components, like PLCs, DCSs, and SCADA systems, require defining processing capacity, communication protocols (e.g., Modbus, Ethernet/IP), and cybersecurity features. Referencing ISA standards and utilizing the ISA Automation Dictionary ensures consistent terminology. Proper component definition minimizes integration issues, enhances system reliability, and supports effective troubleshooting and maintenance throughout the automation system’s lifecycle.

Domain 3: System Design

System Design translates defined requirements into a detailed blueprint, encompassing PFDs, P&IDs, and control system architecture, ensuring seamless integration and functionality.

Process Flow Diagram (PFD) Development

PFD development is a foundational step in system design, visually representing the major equipment and process flow within a system. These diagrams utilize standardized symbols to illustrate unit operations, key process streams, and critical control loops.

A well-constructed PFD serves as a communication tool for engineers, operators, and stakeholders, providing a high-level overview of the process. It’s essential for identifying potential bottlenecks, safety concerns, and optimization opportunities early in the design phase.

PFDs typically include information such as stream compositions, temperatures, pressures, and flow rates, offering a concise yet informative depiction of the process. They form the basis for more detailed diagrams like P&IDs.

Piping and Instrumentation Diagram (P&ID) Creation

P&ID creation builds upon the PFD, providing a detailed graphical representation of the process, including all piping, equipment, instrumentation, and control systems. These diagrams utilize specific symbols to denote each component, adhering to industry standards for clarity and consistency.

P&IDs are crucial for detailed engineering design, hazard analysis, and operational procedures. They illustrate control loops, safety interlocks, and shutdown systems, ensuring safe and efficient operation. Every valve, instrument, and pipe segment is meticulously documented.

Accuracy in P&ID development is paramount, as they serve as the primary reference for construction, commissioning, and ongoing maintenance activities throughout the plant lifecycle.

Control System Architecture Design

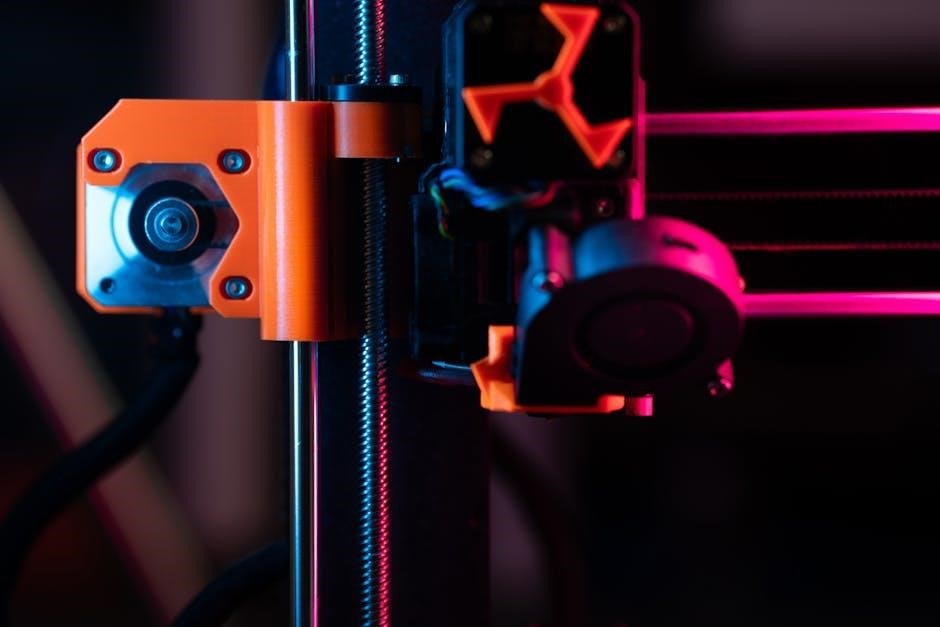

Control system architecture design defines the overall structure and communication pathways of the automation system. This involves selecting appropriate control hardware – PLCs, DCS, or hybrid systems – based on process complexity, safety requirements, and scalability needs.

Key considerations include redundancy, network topology, data security, and integration with other enterprise systems. A well-designed architecture ensures reliable control, efficient data management, and minimized downtime. It also facilitates future expansion and modifications.

The architecture must align with ISA standards and incorporate best practices for cybersecurity, safeguarding the process from unauthorized access and malicious attacks.

Domain 4: Implementation

Implementation encompasses procurement, installation, and commissioning of automation equipment, culminating in Factory Acceptance Testing (FAT) to verify system functionality before deployment.

Procurement of Automation Equipment

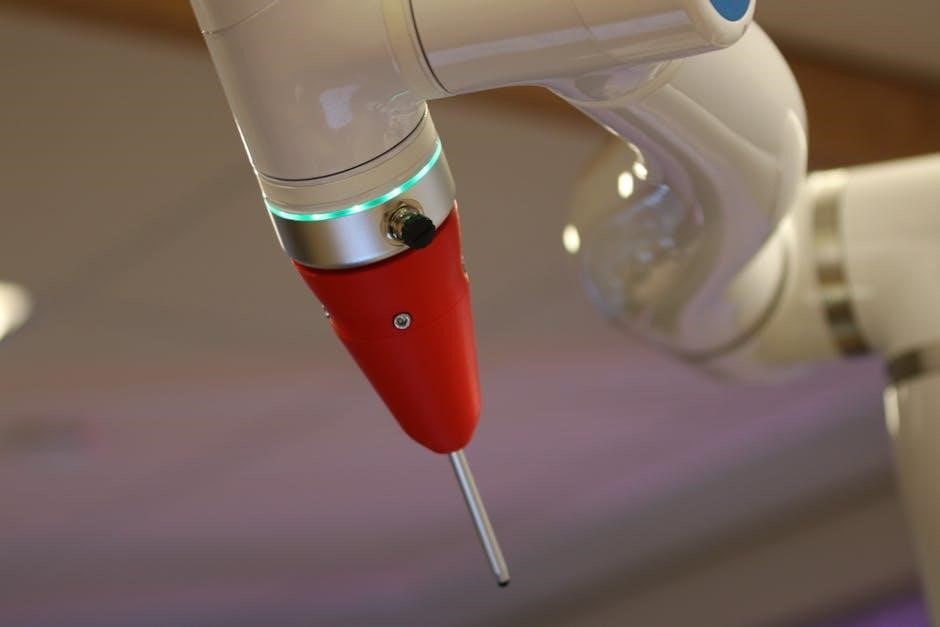

Effective procurement is a critical phase, demanding detailed specifications derived from the Definition domain. This involves identifying qualified vendors capable of supplying reliable and compatible automation components – PLCs, HMIs, sensors, actuators, and more.

A robust Request for Quotation (RFQ) process ensures competitive pricing and adherence to project requirements. Technical evaluations, alongside commercial considerations, are paramount. Vendor selection should prioritize not only cost but also factors like delivery timelines, support services, and long-term viability.

Purchase orders must clearly articulate specifications, quantities, and acceptance criteria. Rigorous inspection upon delivery verifies conformity to ordered specifications, preventing costly delays during installation and commissioning. Documentation, including manuals and certifications, must be meticulously maintained.

Installation and Commissioning

Proper installation, adhering to manufacturer guidelines and safety regulations, is fundamental. Qualified technicians should execute the physical mounting of equipment, wiring, and network connections, ensuring correct grounding and shielding. Detailed documentation of all connections is essential for future troubleshooting.

Commissioning systematically verifies the functionality of each component and the integrated system. This includes power-up tests, loop checks, and calibration of instruments. Software configuration and parameterization are crucial steps, demanding meticulous attention to detail.

Thorough testing under various operating scenarios validates system performance against defined requirements. A documented commissioning report confirms successful completion and serves as a baseline for future maintenance and optimization efforts.

Factory Acceptance Testing (FAT)

Factory Acceptance Testing (FAT) is a critical quality gate, conducted at the vendor’s facility before shipment. It verifies that the automation system meets the specified requirements and design criteria. This proactive approach minimizes on-site issues and reduces project risks.

FAT typically involves simulating real-world operating conditions, testing control logic, and validating communication protocols. Detailed test procedures, collaboratively developed with the end-user, ensure comprehensive coverage. Documentation of test results, including pass/fail criteria, is paramount.

Successful FAT provides confidence in the system’s functionality and reduces costly rework during site acceptance testing. It demonstrates the vendor’s commitment to quality and facilitates a smoother, more efficient project implementation.

Domain 5: Operation and Maintenance

Effective operation and maintenance require detailed SOPs, preventative schedules, and clear troubleshooting guides to ensure system reliability and longevity throughout its lifecycle.

Standard Operating Procedures (SOPs)

Standard Operating Procedures (SOPs) are foundational to consistent and safe automation system operation. These documented instructions detail the precise steps for routine tasks, encompassing startup, shutdown, normal operation, and emergency responses.

Well-defined SOPs minimize human error, ensuring operators follow established best practices, leading to predictable system behavior and enhanced safety. They should clearly outline required parameters, acceptable ranges, and expected outcomes for each process stage.

Regular review and updates are vital, reflecting changes in equipment, software, or process requirements. Comprehensive SOPs contribute significantly to operational efficiency, reduced downtime, and improved product quality, forming a cornerstone of a robust automation lifecycle management strategy.

Preventative Maintenance Schedules

Preventative Maintenance Schedules are critical for maximizing the reliability and lifespan of automation equipment. These schedules outline routine inspections, cleaning, lubrication, and component replacements performed at predetermined intervals.

A proactive approach, preventative maintenance minimizes unexpected failures, reduces costly downtime, and ensures consistent system performance. Schedules should be based on manufacturer recommendations, operating conditions, and historical failure data.

Effective schedules incorporate detailed checklists, assigned responsibilities, and documentation procedures. Implementing a computerized maintenance management system (CMMS) streamlines scheduling, tracking, and reporting. Consistent adherence to preventative maintenance schedules is a key element of a successful long-term automation strategy.

Troubleshooting and Repair Procedures

Troubleshooting and Repair Procedures are essential for swiftly restoring automation systems to operational status following failures. These procedures should be clearly documented, outlining step-by-step diagnostic steps, potential causes, and corrective actions.

Effective procedures prioritize safety, utilizing lock-out/tag-out protocols and appropriate personal protective equipment. Skilled technicians require training in fault finding, utilizing diagnostic tools, and interpreting system logs.

A robust system includes detailed wiring diagrams, component layouts, and spare parts lists. Root cause analysis following repairs prevents recurrence. Maintaining accurate records of troubleshooting steps and repairs builds a valuable knowledge base for future incidents, enhancing overall system reliability.

Domain 6: Performance Monitoring and Optimization

This domain focuses on utilizing KPIs and data analysis to continuously improve automation system efficiency, reliability, and overall performance for sustained value.

Key Performance Indicators (KPIs) for Automation

Establishing relevant KPIs is fundamental to gauging automation success and identifying areas for improvement. These metrics should directly correlate with business objectives, moving beyond simply tracking system uptime.

Essential KPIs include Overall Equipment Effectiveness (OEE), measuring availability, performance, and quality; Mean Time Between Failures (MTBF), indicating system reliability; and production throughput, reflecting process efficiency.

Furthermore, tracking energy consumption, waste reduction, and cycle time variations provides valuable insights. Regularly monitoring these indicators allows for proactive adjustments, ensuring the automation system consistently delivers optimal results and maximizes return on investment. Data-driven decisions, informed by these KPIs, are crucial for continuous improvement.

Data Analysis and Reporting

Effective data analysis transforms raw automation data into actionable intelligence, driving informed decision-making and optimizing system performance. This process involves collecting, cleaning, and interpreting data from various sources – PLCs, SCADA systems, and sensors.

Reporting should be tailored to different audiences, from operators needing real-time insights to management requiring strategic overviews. Visualizations, such as trend charts and dashboards, are crucial for quickly identifying patterns and anomalies;

Advanced analytics, including statistical process control and predictive modeling, can uncover hidden correlations and anticipate potential issues. Comprehensive reporting, coupled with thorough analysis, ensures continuous improvement and maximizes the value of automation investments.

Continuous Improvement Strategies

Automation isn’t a ‘set it and forget it’ endeavor; continuous improvement is paramount for sustained success. Regularly reviewing KPIs and performance data identifies areas for optimization, fostering a culture of proactive refinement.

Implementing methodologies like Lean Manufacturing and Six Sigma can streamline processes and reduce waste within automated systems. Root cause analysis, following unexpected events, prevents recurrence and enhances system reliability.

Embracing new technologies and software updates keeps automation systems current and competitive. Regularly scheduled audits and performance evaluations, alongside employee training, are vital components of a robust continuous improvement program, maximizing ROI.

Supporting Resources and Standards

ISA standards provide a foundational framework, while SCORM and e-learning facilitate uniform training. Software Engineering Body of Knowledge principles enhance automation projects.

ISA (International Society of Automation) Standards

ISA plays a pivotal role in establishing and promoting globally recognized standards for automation, systems, and instrumentation. Their comprehensive catalog includes software tools and detailed documentation supporting various engineering activities throughout the automation lifecycle.

Notably, the ISA Automation, Systems, and Instrumentation Dictionary offers precise definitions for terminology, ensuring clarity and consistency in communication. These standards cover a broad spectrum, from safety instrumented systems (SIS) to distributed control systems (DCS), and are frequently referenced in automation projects worldwide.

Adhering to ISA standards enhances system reliability, interoperability, and safety, ultimately contributing to improved operational efficiency and reduced risk. Utilizing these resources is vital for professionals seeking to implement best practices in automation.

SCORM and e-Learning for Automation Training

SCORM (Sharable Content Object Reference Model) and e-learning platforms are increasingly utilized to deliver standardized automation training. These technologies ensure uniform content delivery and tracking of learner progress, offering scalability and cost-effectiveness.

However, simply completing an e-learning module doesn’t guarantee true competency. Auditors and employers require demonstrable proof of skill application, not just a completed status. Effective training programs must incorporate practical exercises and assessments.

Integrating SCORM-compliant content with hands-on simulations and real-world case studies is crucial for developing a truly skilled automation workforce. This blended approach bridges the gap between theoretical knowledge and practical application, fostering genuine expertise.

Software Engineering Body of Knowledge Relevance

The Software Engineering Body of Knowledge (SWEBoK) holds significant relevance to automation, as modern automation systems heavily rely on software for control, monitoring, and data analysis. Understanding software development principles, testing methodologies, and lifecycle management is paramount.

SWEBoK provides a foundation for building robust, reliable, and secure automation software. Concepts like requirements engineering, design patterns, and quality assurance directly translate to improved automation system performance and reduced downtime.

Leveraging SWEBoK’s collective knowledge ensures that automation projects adhere to industry best practices, minimizing risks and maximizing the return on investment. It fosters a holistic approach, integrating software expertise with process control knowledge.